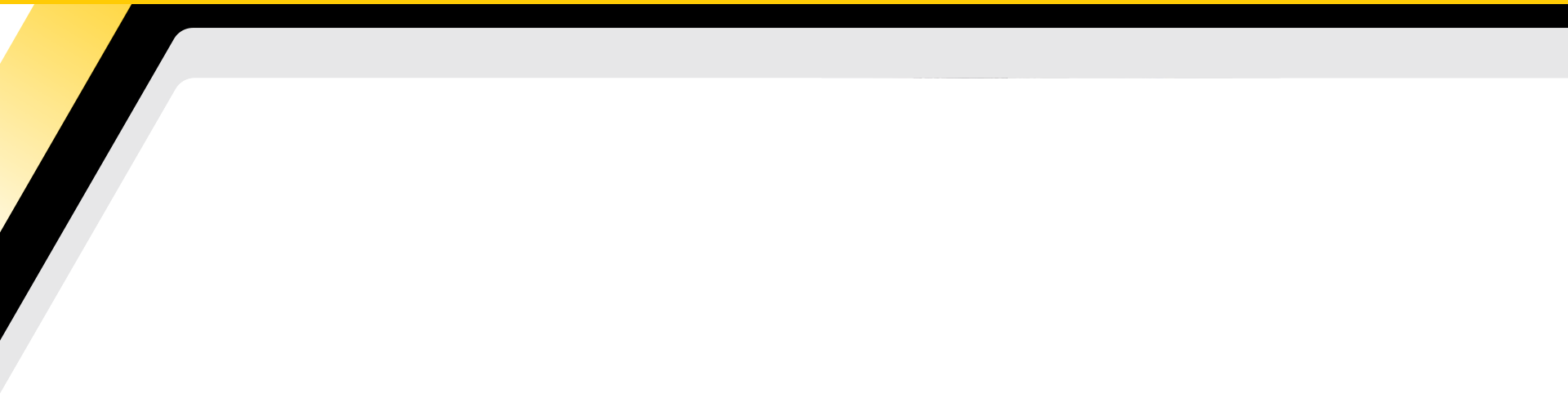

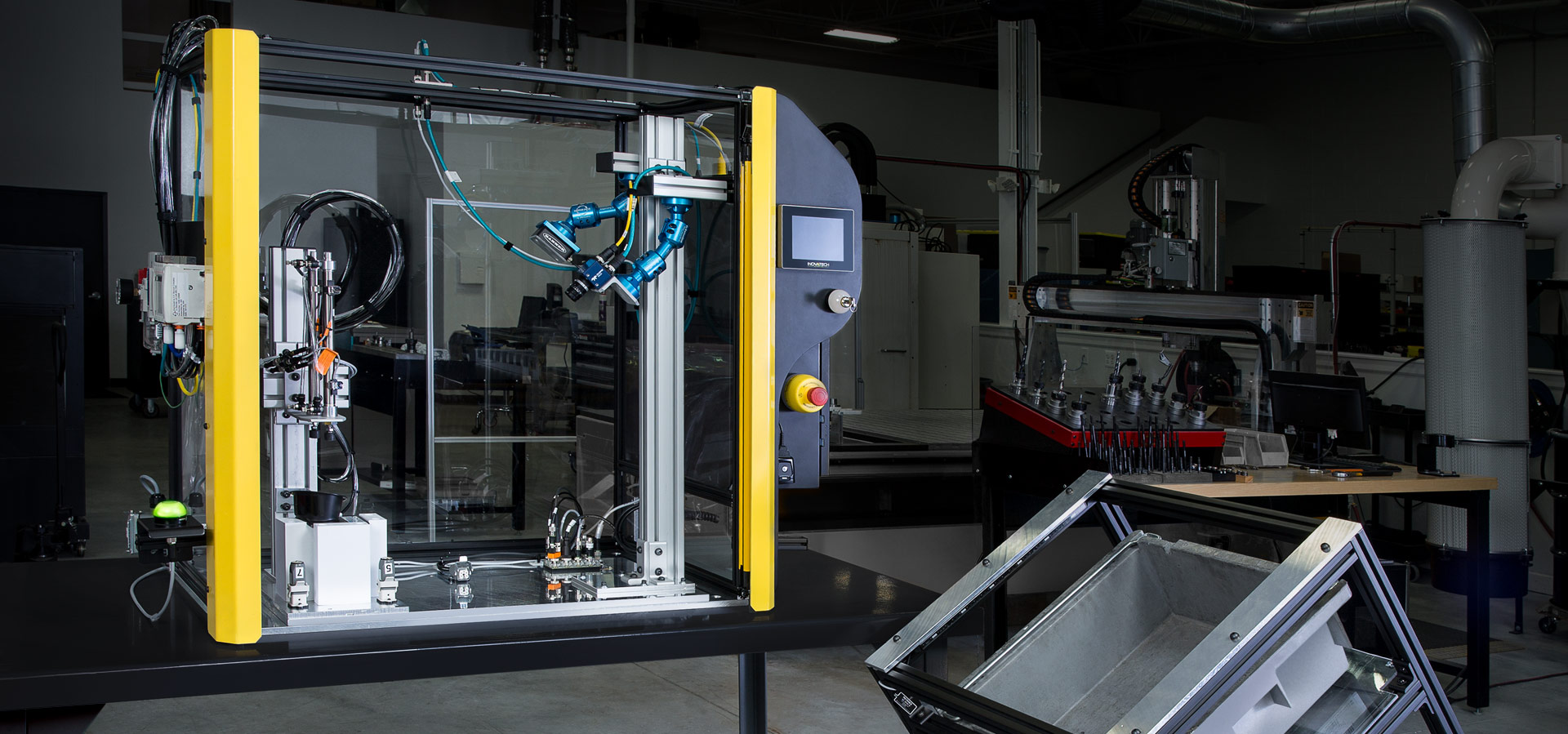

Inovatech Fixtures are customized to fit the demands of modern manufacturing.

An Inovatech fixture is custom made to spec and there really is no limit to what we can build. Our standards run high, assuring that an Inovatech fixture is the best available fixture available today.

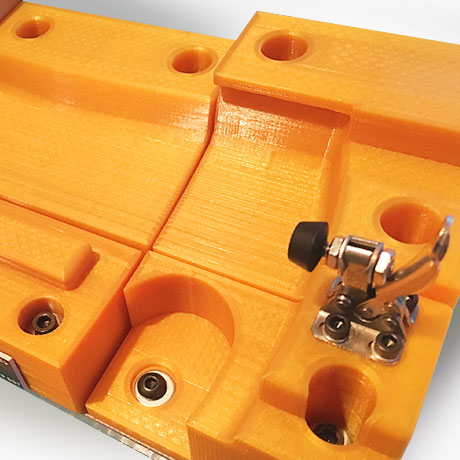

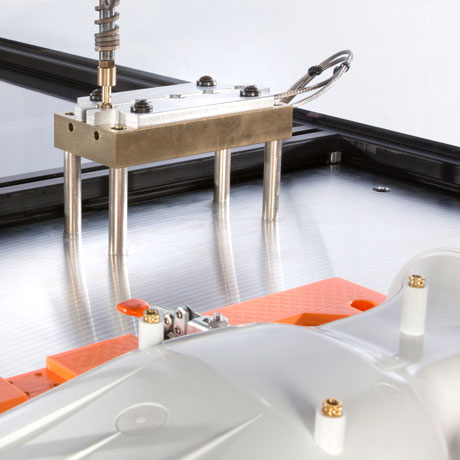

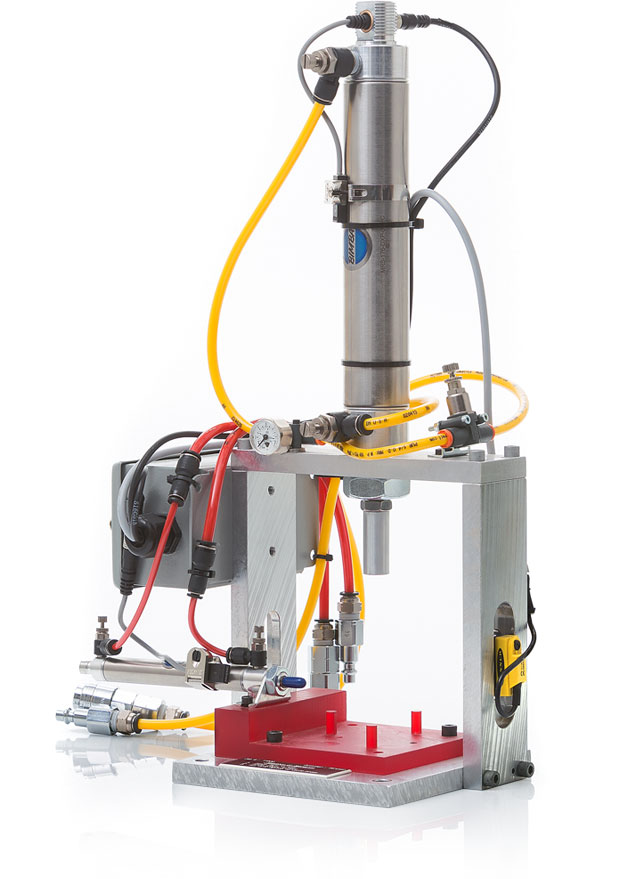

Our engineers work hand-in-hand with your team to assure that your fixture meets your specifications. We’ll discuss the design and immediately begin spec’ing the appropriate components for a successful part. We can accept most CAD files, required for 3D printing, to provide a perfect fit.

Inovatech fixtures and secondary aids, include:

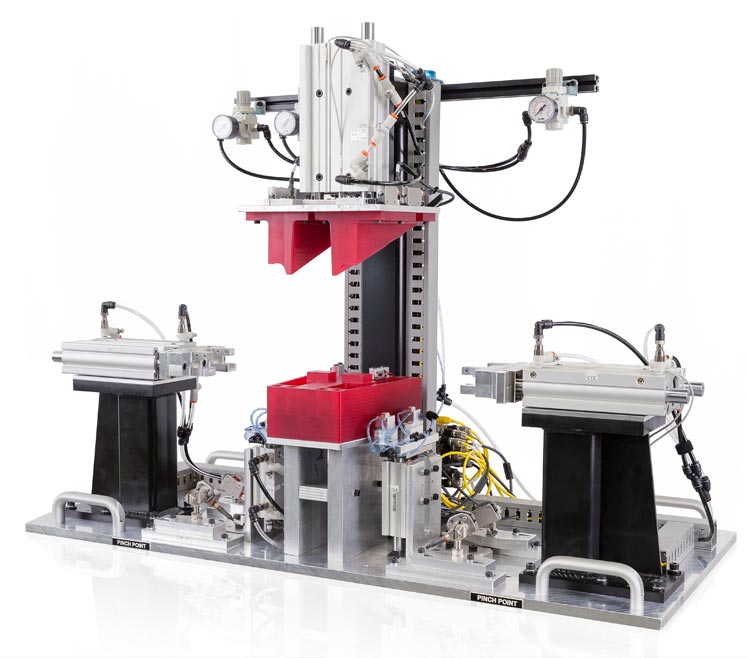

- Simple Nests

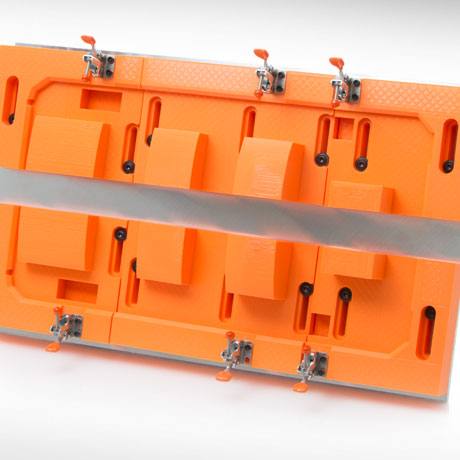

- Degaters

- Thermal Inserting

- Edge-Biter Clip Installation

- Spring Nut Installation

- Error-Proofers

- Foam Seal Installation

- Sonic Welders

- Screw Drivers

- Heat Stake Cells

Complex Fixtures that take the Complexities out

of Manufacturing

IQ-OQ-PQ

We accommodate cleanroom requirements and assist in validating

equipment to adhere to the medical device validation process of IQ-OQ-PQ.